Finding a replacement hose for your application can be daunting; Masterflex Technical Hoses Ltd can help identify and supply the correct product to satisfy your requirements. Please contact our highly experienced sales team for help find your replacement hose, or for more complicated applications, a member of our technical sales team can also visit your site upon request.

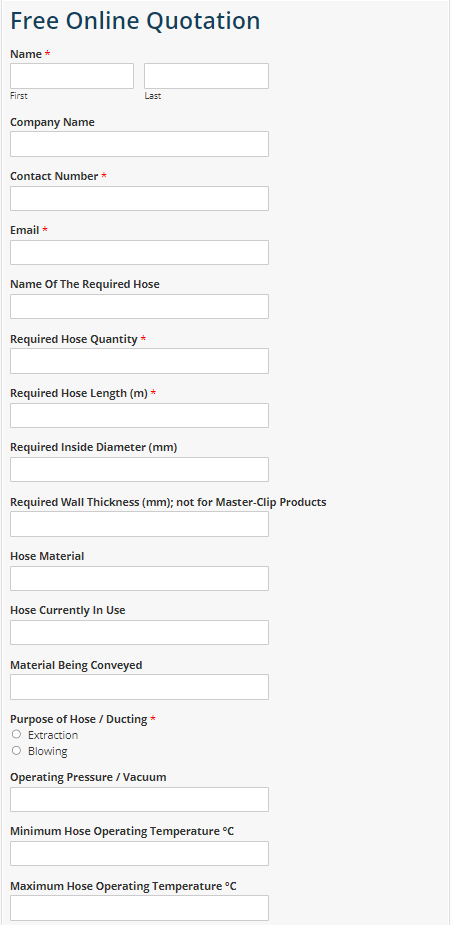

You may also conveniently use our Free Online Quotation Form (SEE BELOW) for a detailed quote.

Large Variety of Hoses at Masterflex, But Why?

There is a large variety of similar-looking hoses manufactured and distributed at Masterflex, with various colours, shapes, sizes. All hoses, with unique specifications, satisfy individual/specific application requirements.

Selecting the Ideal Hose & Duct

(See Your Free Online Quotation Form)

Hose Application & Hose Dimensions

The most dependable way to select a hose for an application is to know basic details of the application along with the hose dimensions:

- Minimum & Maximum Hose Operating Temperatures (1)

- Materials Being Conveyed (2)

- Operating Pressures (3)

- Purpose of Hose: blowing/extraction

- Hose Dimensions:

- Hose Length

- Inside Diameter

- Wall Thickness of the current product, if known

1. Minimum & Maximum Hose Temperature Range:

Hoses used outside their temperature range may lead to hardening of the hose material cracking or even melting, resulting in hose failure. Therefore, where possible it is essential to identify the operating temperatures for hoses.

Following are examples of hoses suitable for high temperatures:

- Master Clip HT 450 – High Temperature up to -20ºC to 450ºC

- Master Clip HT 1100 – Extreme Temperature up to -20ºC to 1100ºC

- Master SIL 2 – High-Temperature Silicone-coated glass-fibre fabric Hose up to -70ºC to +250ºC

View all High-Temperature Hoses

2. Materials Being Conveyed:

Knowledge of the hose transfer media, e.g. vapour, dust, granules and aggregates, along with relevant chemical nature, is essential when selecting the correct hose.

Application variables, including environment, the frequency of usage and whether the application requires adherence to any standards, are other points to consider when selecting a hose. Examples of industry-standard hoses include:

- Food Grade Hoses (FDA approved)

- Flame Retardant Hoses (DIN 4102:B1)

- Electroconductive Hoses (ATEX approved)

The physical properties of the hoses are also important: Applications may require a certain amount of flexibility or robustness. Hose properties can range from lightweight and highly flexible to extremely abrasion resistant at the expense of flexibility.

Our hose products range from Lightweight PVC, light to heavy-duty polyurethane and other fabric-based material products. Our (Master Clip) fabric-based hoses are manufactured from materials, including PVC, Neoprene, Hypalon, Silicon and High-Temperature Fabrics. These materials have different properties, including varying abrasion resistance, flame resistance and static dissipation qualities.

3. The Operating Pressures

Hoses can tolerate negative (extraction/suction) or positive pressures up to specific values; Identifying operating pressures will help narrow down your hose selection and prevent the hose from collapsing, bursting or leaking.

Hose operating pressures and vacuum ratings are usually related to the hose’s inside diameter, wall thickness and helix pitch. Within the Masterflex Range, the following products have the highest operating pressures:

- Master Pur HX: Polyurethane Food Grade Hose

- Cargoflex: PU Suction hose & Transport hose

- Master-PUR Inline: PU Suction & Transport Hose

Find Your Replacement Hose – Let Us Help You Discover Your Replacement Hose, Best for Your Needs

For selecting highly compatible hoses for your application, our Sales Team would be glad to assist you. Please give Masterflex UK a call today or complete the online form:

Prince of Wales Business Park Units G – H, Vulcan St, Oldham OL1 4ER

Monday – Thursday: 8 AM – 5 PM

Friday 8 AM – 2:30 PM

Phone: 0161 626 8066