Robot Hose Failure: At Masterflex, we understand hoses’ critical role in the smooth operation of your robotic and automation systems. These systems endure constant movement, extreme temperatures, and exposure to various chemicals. Regular hoses can easily succumb to such harsh conditions, leading to costly downtime and malfunction.

This is where our highly flexible and stress-crack-resistant high-performance hoses come in. They are specifically designed to withstand the demanding environment of robotics and automation.

Say Goodbye to Hose Cracks

Our hoses are built with superior materials and cutting-edge manufacturing techniques, making them exceptionally resistant to:

- Abrasive substances that can wear down lesser hoses.

- Chemical influences can cause cracks and degradation.

- Extreme temperatures can compromise hose integrity.

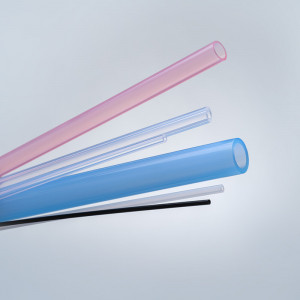

FEP Hoses: The Non-Stick Champions

A particularly notable example is our FEP hose. This hose is constructed from fluorinated ethylene propylene (FEP), a material known for its:

- Exceptional smoothness: This makes cleaning easy and prevents substances from sticking to the hose interior.

- Superior chemical resistance: FEP hoses can handle various chemicals commonly used in industrial settings.

- Electrical insulation and non-flammability: An important safety feature for applications with electrical hazards.

Masterflex: Your Partner in Performance

We are confident that our hoses can deliver long-lasting and reliable performance, even in challenging environments. Whether you operate in:

- Assembly lines

- Material Handling

- Complex automation systems

Our hoses provide the flexibility, versatility, and durability your application demands.

PA Duopart®: The Double Threat Against Damage

The PA Duopart® is a double polyamide hose that stands out for its ability to resist both mechanical and chemical damage:

- Highly abrasion-resistant walls: These walls can handle constant movement and contact with rough surfaces without wearing down.

- Insensitivity to stress corrosion cracking: This ensures the hose won’t develop cracks under pressure.

- Impressive chemical resistance: The PA Duopart® can withstand exposure to various chemicals, solvents, oils, and UV radiation.

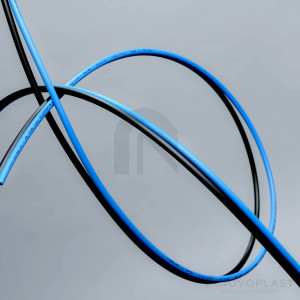

Designed for Tight Spaces

The PA Duopart® also boasts a small bending radius. This makes it ideal for the often space-constrained environments in robotics and automation applications.

Masterflex: Solutions for Every Industry

Our high-performance hoses find application in a vast range of industries, including:

- Agriculture

- Automotive

- Plant & mechanical engineering

- Robotics & automation (of course!)

- Semiconductor industry

- Aerospace technology

- And many more!

Ready to Take Your Robotics and Automation to the Next Level?

By optimizing your system with Masterflex hoses, you can expect:

- Reduced downtime: Fewer hose failures mean less time spent on repairs and replacements.

- Increased productivity: Your systems will function smoothly and efficiently for longer periods.

- Enhanced process efficiency: Reliable hoses contribute to a more streamlined operation.

Join us on LinkedIn!

We encourage you to follow us on LinkedIn for regular updates, industry insights, and valuable content related to robot hose failure, our hose solutions and their applications in robotics and automation.

Contact us today to discuss your needs and discover how Masterflex hoses can elevate your operations.

Don’t settle for hoses that compromise your performance. Choose Masterflex and experience the difference!